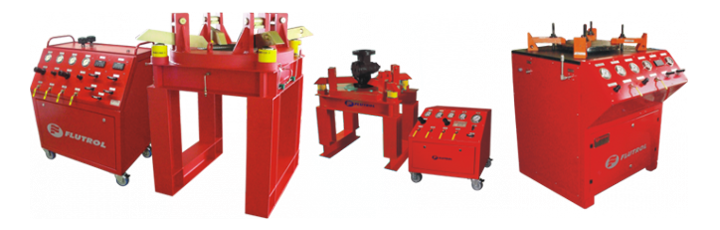

Test bench - Valve

The market for industrial valves has been growing very fast in Brazil, requiring increasingly rigorous tests in order to meet the requirements of Quality Assurance.

Valves

Valves for process control

Drawer

Ball

Globe

Retention

Butterfly

Diaphragm

Safety and relief valves (PSV)

Subsea

Fittings

Flanged

Threaded

Welded

The type of test depends on the valve and the application, among the most common are:

Body testing

Pressure applied inside the valve body

Backseat test

Pressure applied inside the valve body with backseat test

Test with valve fully open or fully closed

Safety valve test

Opening pressure using the "POP" test system

Leak test at 90-95% of the opening pressure

Special Tests

Tests with Nitrogen

Fatigue Testing

Cycle Testing with Actuators

Subsea Requirement Tests

Sealing test for high and low pressure

Pressure applied to each side of the closed valve

The high pressure test is performed with a pressure 1.1 times or more of the maximum working pressure

The low pressure test is performed with a pressure of 5 to 7 bar of compressed air, detected by air bubbles of a water column

FLUTROL specializes in the design and manufacture of valve test benches meeting Quality Assurance requirements for a wide range of customers and various types of valves and pressures.

Types of bench mounting

Manual mechanics

Manual Hydraulics

Automatic CLP hydraulics

Basic components

Haskel Compressed Air / Nitrogen Pressure amplifier;

Pressure control through gauge or digital indicator;

Valve mounting bench, manual or automatic;

Instrumentation, valves, piping and oversized fittings to operate with maximum safety in these pressure classes, assembled and tested;

CLP control system, if applicable;

Panel with instrumentation and valves, arranged in a manner that facilitates operation;

Safety doors and/or windows (optional);

Data acquisition system for the printing of the test curves (optional).

contato@flutrol.com.br

contato@flutrol.com.br +55 11 2940.9053

+55 11 2940.9053